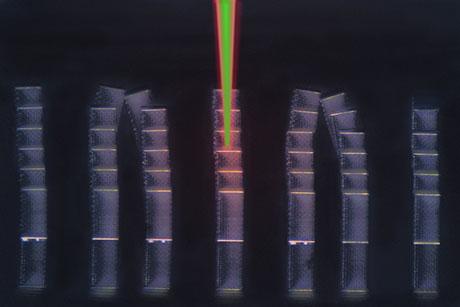

Iridescent Displays

MechE Alum Leads a Revolution in Displays

Clarence Chui (PhD ‘98)

(Photo credit: Ken Hansen)

Clarence Chui (PhD ‘98), senior vice president and general manager of Qualcomm’s MEMS Technologies, producer of a radical new display that boasts full color in sunlight and low power usage, describes some of the technology behind his team’s discovery and his role in helping to shape it.

How did the team come up with the idea to simulate the mechanism for iridescent color in butterfly wings?

The mechanism responsible for the iridescent color in butterfly wings has been known for some time, and is also responsible for the naturally produced colors one sees in a soap bubble or in an oil slick. Two French scientists (Fabry and Pérot) discovered how optical interference (etalons) can alter wavelengths of light way back in the early 20th century.

Your displays are able to achieve full color even in direct sunlight and consume less energy than most displays. How?

At the most basic level, a mirasol display is an optically resonant cavity. The device consists of a self-supporting deformable reflective membrane and a thin-film stack (each of which acts as one mirror of an optically resonant cavity), both residing on a transparent substrate. When ambient light hits the structure, it is reflected both off the top of the thin-film stack and off the reflective membrane. Depending on the height of the optical cavity, light of certain wavelengths reflecting off the membrane will be slightly out of phase with the light reflecting off the thin-film structure. Based on the phase difference, some wavelengths will constructively interfere, while others will destructively interfere. The human eye will perceive a color as certain wavelengths will be amplified with respect to others. The image on a mirasol display can switch between the selected color and black by changing the membrane state. This is accomplished by applying a voltage to the thin-film stack, which is electrically conducting and is protected by an insulating layer. When a voltage is applied, electrostatic forces cause the membrane to collapse. The change in the optical cavity now results in constructive interference at ultraviolet wavelengths, which are not visible to the human eye. Hence, the image on the screen appears black. A full-color display is assembled by spatially ordering IMOD elements reflecting in the red, green and blue wavelengths.

What do you consider to be the most revolutionary about your displays?

Mirasol displays are a technology breakthrough that delivers substantial performance benefits over competing display technologies. Never before has a single display technology supported color and interactive content while also offering crisp visibility inside and outdoors with energy efficiency to provide weeks of battery life. Our displays use microscopic mirrors to reflect ambient light. This means they do not use a backlight, one of the largest consumers of power in today’s backlit displays. Mirasol displays are also bi-stable, which allows for near-zero power usage in situations where the display image is unchanged. This means that mirasol displays benefit from considerable power savings, especially compared to displays that continually refresh, such as LCDs.

|

| Image courtesy of Qualcomm |

If it’s lit by the sunlight, how does the display work in the dark?

Qualcomm has developed a front light solution that is integrated into mirasol devices. The front light can be switched on when needed and consumes only a small amount of energy compared to an LCD’s back light. Our goal is to provide a consistent viewing experience regardless of ambient light conditions.

How is your manufacturing affected by this new process of creating displays?

While the technology behind mirasol displays is unique, the manufacturing processes (and tools and materials) share many similarities with other mainstream display technologies, including LCD. MEMS are unusual in the display world but have a broad application in other industries.

What was your role in the R&D and production of these new displays?

I met the founders of Iridigm, the startup that came up with the technical concept behind mirasol displays, while I was working at a consulting firm, Exponent, in the Boston area. The inventor and his co-founder were both MIT alums and we were introduced by another alum, who happened to be my supervisor at the firm. Even though some of the still image optical demonstrations of the technology were fantastic at the time, there was very little understanding of how the relationships between mechanical stress, device geometry, material thicknesses, and environmental conditions were interconnected and could be optimized to create a properly functioning full display. After all, the basic device is mechanical in nature and so the mechanical properties are really critical to understand. I started out as a consultant to Iridigm and my first task was to put together an analytical framework within which the relationships amongst these key attributes could be understood so device designs and fabrication efforts could be guided by criteria that gave us the best chance to create a good-looking, active display. That initial analysis was fruitful enough that when the company moved from Boston to the Bay Area they asked me to join full time, which I happily did toward the end of 1999. The analytical model become the basis for a lot of the early decisions we made in adjusting the material choices, design parameters, and fabrication methods. Versions of that analysis were used for quite a few years afterward as a tool to help subsequent engineers understand how all the basic parameters were interrelated. We didn’t have enough funding during the early stages of the company to afford sophisticated simulation tools so having a set of simple scaling relationships was really important for getting a good “feel” for how devices ought to be designed. Over time, I also made contributions to areas beyond the basic device like display systems and drive scheme methods, especially the techniques for defining, sequencing, and delivering voltage waveforms that would help produce good-looking images. I especially liked working on this part of the technology because it was a lot like trying to solve a puzzle by figuring out what combinations of waveforms, voltage levels, timing, and image processing could coax the best performance out of the display. The resulting solutions were definitely not obvious at the outset, since the displays and system typically had a significant amount of uncharacterized behavior to them in the beginning. So it’s very satisfying at the end when you see what combinations of things end up in the product. I think the biggest lesson I’ve learned so far is that it takes very long to make changes in the materials and manufacturing processes involved in making MEMS, so getting performance improvements by other means has to be an essential part of this type of commercialization effort. As the organization has grown, my contribution has primarily been helping to build and mentor the teams involved in the day-to-day development activity, with the intermittent direct contribution of ideas. Many of the initial concepts have made their way into the commercial products, so that part of my role has been very satisfying. I’m also extremely pleased that many of the ideas that have made it into our products or are being planned into our roadmap have come by unexpected means or sources. From a technology and product development point of view, one of the best contributions I can make at this point is to try to get out of the way of our highly capable teams.

How did your studies at MIT help prepare you for this role?

I suppose I could say a bunch of the normal general things like how the training helped encourage my natural curiosity, or that my exposure to the analytical methods involved in the coursework and thesis work provided me with a broad skillset that helped make professional opportunities including Iridigm and Qualcomm available, or that the great people and learning environment shaped my views of technology during a critical period in my life and probably shaped my perspective within my current role, or many other similar things. Of course, all of those things are true. However, I will point out a specific example where the training helped me. Because of the group I worked in (The Mechanics group within the Department of Mechanical Engineering), I picked up a habit of always trying to redefine complex mechanical or materials problems into a framework that could be solved with reasonable accuracy in an analytical form, say within 15%-25% of the actual solution, or a solution that could be achieved by more sophisticated means, like computational simulation. The habit also lead me to get involved in other classmates’ problems (even those outside of our group or department), especially if they had something mechanical or materials related to them. It allowed me to see that the same kind of methods could be applied to problems outside of the context that I was used to, and probably helped me generalize my problem-solving approach so I could look at problems in other fields and feel confident that I could contribute. It was probably that tendency that lead me to choose engineering consulting as a starting point in my career rather than continue focusing on my specific field of study. I’m sure things would probably have worked out fine either way, but overall I’m grateful that the curriculum and the expectations of my thesis advisor were flexible enough to accommodate my natural tendencies to want to look at many different types of problems. It was this basic skill that eventually allowed me to contribute meaningfully to the fundamental analysis that supports the mirasol-related technologies. The mirasol work just happened to be really amenable to the tools and methods I had practice using as a student and early in my career. It was just coincidentally a very good match.

How do you see this new technology affecting the display market in both the short and long term?

We believe that mirasol displays are a revolutionary advance in display technology, unlike any we have seen previously. The application of this display offers disruptive performance advantages for any device into which mirasol displays are built: delivering color and interactive content, best-in-class energy efficiency, and visibility even in the brightest of outdoor conditions. Because mirasol displays address the inevitable market demand for a color and outdoor-visible display technology that is extremely low power, they enable a wide range of new consumer experiences and new use models.![]()